- Chinese

-

WeChat

Increase the production and stocking of oil-immersed transformer S11 series and dry-type transformer SCB10 series…

Xuzhou Pengcheng Electric Co Ltd Transformer 2019 Annual Meeting Summary…

Xuzhou Pengcheng Transformer actively fights against the new crown epidemic! Helping the construction of the branch hospital of Beijing Luhe Hospital…

Transformer manufacturers tell you what are the adverse effects of high transformer temperature…

Transformer load test purpose…

Transformer manufacturers demystify - the basic knowledge of dry-type transformers…

Want to know the price trend of 800kva dry type transformer?…

There are so many transformer manufacturers out there, do you know which one to choose?…

What is the structure of an oil-immersed transformer?…

Energy-saving and Environmentally Friendly Dry-type Transformers…

The load loss of a dry-type transformer accounts for 70% to 80% of the total loss, including the winding DC resistance loss (basic loss), conductor eddy current loss, loop current loss between parallel winding conductors, lead loss and shunt loss of structural components (such as plywood, steel plates, box walls, bolts, core plates, etc.). The main methods to reduce load loss in dry-type transformers are as follows.

The additional losses caused by leakage flux in dry-type transformers are limited by balancing the ampere-turns calculation. Based on the results, the ampere-turns are adjusted. The windings are arranged in a "low-high-low" or "high-low-high" configuration. The width and thickness of the flat wires are limited. The optimal position conversion method is selected through magnetic field calculations.

The size of the main insulation structure and vertical insulation structure of dry-type transformers is reduced. The high-voltage winding adopts the "equal impact voltage gradient" distribution technology, which can reduce the size of the longitudinal insulation. Thin paper tubes are used, with very small oil gaps between the windings. The main insulation is made using cardboard. Components of the same shape are used, with equipotential forming parts to ensure that the shape of the corner ring and the equipotential line are consistent. Axial oil ducts are set, and ethyl acetate varnish-wrapped wire is commonly used. Q-2 or QB type ethyl acetate wire is used to replace 0.45mm thick paper-wrapped flat wire. Since the first two layers of insulation are 2×(0.056-09.79)mm, the winding factor is high, and the winding insulation must meet the requirements. The stress is small; the distance of the main insulation (diameter, end) is appropriately reduced.

The dry-type transformer follows the corresponding processes based on calculations. The longitudinal insulation structure is determined according to impulse calculations, and the chamfer of the spacer, column, and metal parts is maintained in good shape. The leakage magnetic field and eddy current distribution are calculated to guide displacement. The winding axis is evenly distributed. The core pillars are made of non-magnetic materials. Special shielding is applied to the core pillars and magnetic yokes to reduce the electric field. The voltage adjustment windings are connected sequentially. An assembly method is used, with the inner winding directly wound. The insulating tubes are strictly controlled for height and diameter tolerance, and new technologies with small inter-group gap volumes and thermal covers are adopted. An integrated support plate and pressure plate are used, and when changing the winding position, pressure-dried dynasian paper is applied, with the windings placed in a dry insulation room to prevent moisture.

|

上一条:Analysis of the Three Main Causes of Transformer Burnout 下一条:S11 Oil immersed Transformer Structure |

产品推荐

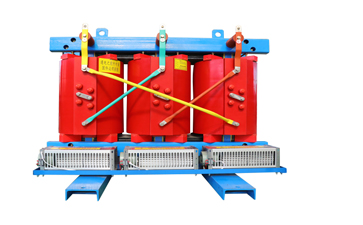

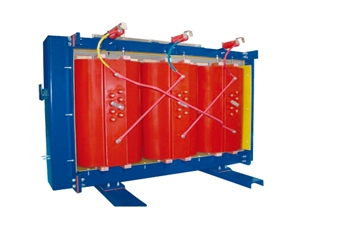

630kva-scb10 Dry Type Transformer

查看更多 +

SCB13 Dry Type Transformer

查看更多 +

SCB10 Dry Type Transformer

查看更多 +

SCB11 Dry Type Transformer

查看更多 +

SCBH15 Dry type Amorphous Alloy Transformer

查看更多 +

SGB10 Non-encapsulated Coils

查看更多 +

S11 Oil Immersed Transformer

查看更多 +

S13 Oil Immersed Transformer

查看更多 +